Warum muss die Druckindustrie Keramik-Rasterwalzen verwenden?

Der Druck von Karton und Wellpappe erfordert in der Regel große Flächen, was hohe Anforderungen an die Drucktechnik stellt. Keramik-Rasterwalzen meistern die Herausforderungen des Großflächendrucks in diesem Bereich effektiv. Ihre präzise Farbsteuerung gewährleistet nicht nur eine gleichmäßige Musterabdeckung, sondern vermeidet auch übermäßigen oder unzureichenden Farbauftrag und verbessert so die Druckqualität von Karton und Wellpappe.

Bei der Herstellung von Kartons und Wellpappe sorgen die Verschleißfestigkeit und Korrosionsbeständigkeit von Keramik-Rasterwalzen dafür, dass die Walzen auch über lange Nutzungsdauer eine stabile Leistung erbringen. Dies ist insbesondere bei großen Produktionslinien wichtig, da dadurch die Wartungshäufigkeit und die Austauschkosten der Anlagen reduziert und die Produktionseffizienz verbessert werden können.Beispielsweise können Keramik-Rasterwalzen bei der Herstellung individueller Kartons die Klarheit und Farbgenauigkeit gedruckter Muster sicherstellen, sodass die Kartons nicht nur hervorragende Schutzfunktionen aufweisen, sondern auch attraktive visuelle Effekte erzielen.Was ist bei der Auswahl von Keramik-Rasterwalzen zu beachten?

Dichte und Form der Rasterwalze wirken sich direkt auf die Menge und Verteilung der Farbübertragung aus. Bei der Auswahl einer Keramik-Rasterwalze ist es wichtig, die passende Rasterwalze entsprechend den Anforderungen der Druckaufgabe auszuwählen. Beispielsweise ermöglicht die Wahl einer Walze mit feiner Rasterwalze für hochpräzise Druckaufgaben eine präzisere Farbkontrolle, während bei großflächigen Beschichtungsaufgaben eine Walze mit größerer Rasterwalze die Effizienz verbessern kann.

Zweitens, der Durchmesser und die Länge der

Keramik-Rasterwalze

Die Auswahl sollte den tatsächlichen Anforderungen der Produktionslinie entsprechen. Größere Walzen eignen sich für den Großformatdruck, während kleinere Walzen für kleinere Druckbereiche geeignet sind. Die Kompatibilität der Walzengröße mit der Produktionslinie kann die Produktionseffizienz und Druckqualität effektiv verbessern.

Die Qualität der Keramik-Rasterwalze hängt nicht nur von der Feinheit des Rastermusters ab, sondern auch von der Qualität des Materials und der Beschichtung. Hochwertige Keramikbeschichtungen sorgen für eine bessere Verschleißfestigkeit und Korrosionsbeständigkeit und verlängern so die Lebensdauer der Walze. Die Auswahl hochwertiger Keramik-Rasterwalzen aus hochwertigen Materialien und Verfahren gewährleistet die langfristige Stabilität der Anlage.

Die Wahl zuverlässiger Lieferanten und Dienstleister ist ein wichtiger Garant für die Qualität und Leistungsfähigkeit von Keramik-Rasterwalzen. Lieferanten sollten detaillierte Produktinformationen und technischen Support bereitstellen und maßgeschneiderte, bedarfsgerechte Lösungen anbieten können. Auch die Qualität des Kundendienstes ist ein wichtiger Faktor bei der Lieferantenauswahl, um auftretende Probleme zeitnah zu lösen.

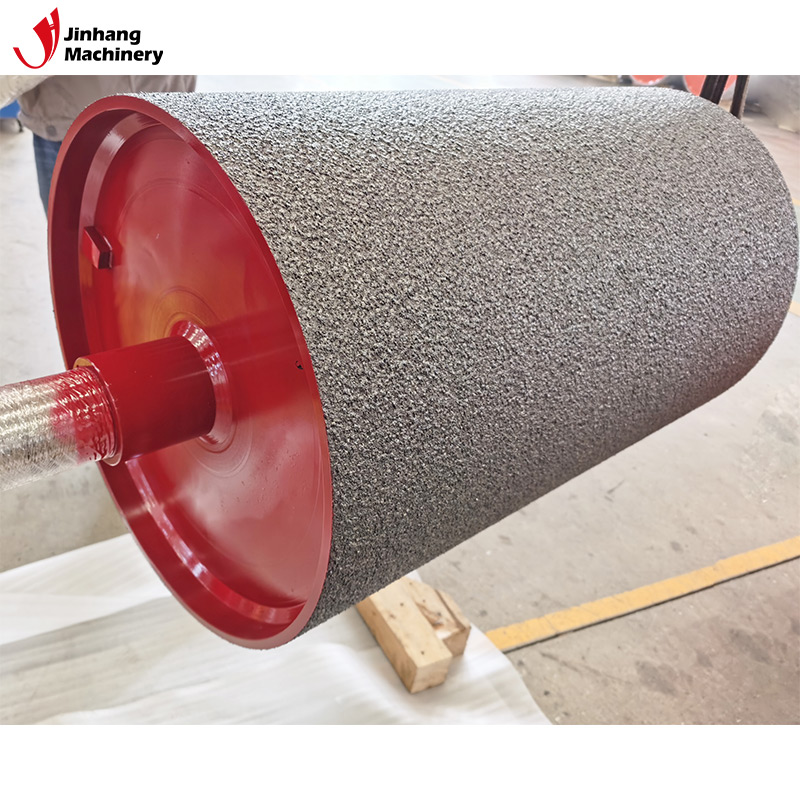

What is a ceramic anilox roller?

A ceramic anilox roller is a roller with a ceramic coating on the surface, which is specially used to control the transfer of ink in flexographic printing. Its surface is engraved with fine anilox structures, through which the ink is brought out of the ink tank and evenly applied to the printing plate.

What are the characteristics of ceramic materials?

Ceramic materials have outstanding performance in flexographic printing due to their superior physical and chemical properties. Ceramic materials have the following main characteristics:

● High hardness and wear resistance: Ceramic materials have extremely high hardness, which can effectively resist the wear and tear generated during the printing process and extend the service life of the anilox roller.

● Strong corrosion resistance: The ceramic surface has good tolerance to the chemical components in the ink and is not easily corroded.

● High precision: The surface texture of the ceramic anilox roller is usually engraved by laser, which can accurately control the amount of ink transferred and ensure the consistency of printing quality.

What is the role of the anilox structure?

The surface texture of the ceramic anilox roller is its core function. These tiny grooves control the amount and distribution of ink through their shape, depth and arrangement. Common anilox shapes include honeycomb, straight line, cross line, etc. Different shapes of anilox are suitable for different printing needs. For example, honeycomb anilox is suitable for delicate printing work, while straight line anilox is suitable for coating larger areas.

What is the role of ceramic anilox roller in flexographic printing?

Ceramic anilox roller plays a core role in flexographic printing. It is not only a carrier of ink, but also a guardian of printing quality. Specifically, ceramic anilox rollers have the following main functions in flexographic printing:

Precise control of ink volume

Flexographic printing requires extremely high precision control of ink. Too much ink will cause the printed pattern to be blurred and the color to be too thick, while insufficient ink will cause uneven color or missing patterns in the printed product. Ceramic anilox rollers can accurately control the amount of ink transferred through their precise anilox structure to ensure the consistency of the amount of ink each time it is printed. The depth, shape and density of the anilox directly affect the amount of ink transferred. Therefore, it is crucial to choose the right ceramic anilox roller according to different printing needs.

For example, when printing fine patterns, the tiny grooves of the ceramic anilox roller can ensure that the ink is transferred in the right amount, avoiding ink overflow at the edge of the pattern, thereby improving the clarity and quality of the printed product.

Improving the quality of printed products

Ceramic anilox rollers can not only control the amount of ink, but also ensure the uniform distribution of ink. During the printing process, the ceramic anilox roller evenly applies the ink to the printing plate through its precise anilox structure, avoiding uneven ink distribution or accumulation, thereby improving the overall quality of the printed product. This is especially important for printing high-quality packaging materials, labels and other products.

For example, when printing high-end food packaging, the patterns and text on the packaging need to be highly accurate and consistent, and the uniform coating function of the ceramic anilox roller can ensure that the packaging looks exquisite and flawless.

Extend equipment life

Flexographic printing equipment often faces the challenges of wear and corrosion in high-intensity production environments. Ceramic anilox rollers, due to their high hardness and corrosion resistance, can effectively extend the service life of printing equipment and reduce the maintenance and replacement frequency of equipment. This not only reduces production costs, but also improves production efficiency.

For example, when using highly corrosive inks or working at high intensity for a long time, ceramic anilox rollers can maintain their stable performance and are not prone to wear or corrosion, thereby ensuring the long-term normal operation of the equipment.

Reduce scrap rate

The high precision and stability of ceramic anilox rollers greatly reduce the scrap rate during the printing process. Since ceramic anilox rollers can ensure the precise transfer and uniform coating of ink, problems such as color difference and unclear patterns in the printing process are effectively avoided, thereby reducing the generation of scrap and improving production efficiency.

For example, in large-scale printing, the stability of ceramic anilox rollers can ensure the consistent quality of each printed product, avoid waste caused by ink problems, and thus save raw materials and production costs.

What are the specific applications of ceramic anilox rollers in flexographic printing?

Ceramic anilox rollers are widely used in flexographic printing, especially in the following areas:

Packaging printing

Packaging printing is one of the main application areas of flexographic printing. Whether it is food packaging, pharmaceutical packaging or industrial packaging, ceramic anilox rollers can ensure high-quality printing effects. By precisely controlling the transfer of ink, ceramic anilox rollers can achieve the clarity and color uniformity of the pattern on the packaging surface, thereby enhancing the market competitiveness of the product.

For example, when printing food packaging bags, the text and patterns on the packaging need to be clear and attractive. Ceramic anilox rollers can ensure the stability and high quality of the printing effect, making the packaging more attractive on the shelf.

Label printing

Label printing requires extremely high printing accuracy, especially in industries such as pharmaceuticals and cosmetics, where the information on the label must be clear and consistent in color. Ceramic anilox rollers excel in this demanding printing task, precisely controlling the amount of ink to ensure clarity and color accuracy of label printing.

For example, in pharmaceutical label printing, any information error can have serious consequences. The precise control of ceramic anilox rollers ensures that label information is accurate and ensures product safety and compliance.

Newspaper and publication printing

Flexographic printing is increasingly used in newspaper and publication printing, and ceramic anilox rollers also play an important role in this field. By precisely controlling the amount of ink, ceramic anilox rollers can ensure the clarity of text and images in newspaper and publication printing, thereby improving the reading experience of readers.

For example, when printing high-quality color magazines, ceramic anilox rollers can ensure that the colors of the pictures are bright and the text is clear and readable, enhancing the reader's visual enjoyment and information communication effect.

Carton and corrugated board printing

Carton and corrugated board printing usually needs to be carried out on a large surface, which places high demands on printing equipment. Ceramic anilox rollers can effectively meet the challenges of large-area printing in this field. Its precise ink control capability not only ensures uniform coverage of the pattern, but also avoids excessive or insufficient ink, thereby improving the printing quality of cartons and corrugated board.

In the production process of cartons and corrugated board, the wear resistance and corrosion resistance of ceramic anilox rollers ensure that the rollers maintain stable performance over long periods of use. This is particularly important for large-scale production lines, which can reduce the maintenance frequency and replacement costs of equipment and improve production efficiency.

For example, when producing customized cartons, ceramic anilox rollers can ensure the clarity and color accuracy of printed patterns, making the cartons not only have excellent protection functions but also provide attractive visual effects.

What are the considerations for selecting ceramic anilox rollers?

The density and shape of the anilox directly affect the amount and distribution of ink transfer. When selecting a ceramic anilox roller, it is necessary to select the appropriate anilox according to the requirements of the printing task. For example, for high-precision printing tasks, choosing a roller with a fine anilox can provide more precise ink control, while for large-area coating tasks, choosing a roller with a larger anilox can improve efficiency.

Secondly, the diameter and length of the ceramic anilox roller should be selected according to the actual needs of the production line. Larger rollers can adapt to large-format printing, while smaller rollers are suitable for smaller printing areas. Ensuring the compatibility of the roller size with the production line can effectively improve production efficiency and printing quality.

In addition, the quality of the ceramic anilox roller depends not only on the fineness of its anilox pattern, but also on the quality of the material and coating. High-quality ceramic coatings can provide better wear resistance and corrosion resistance, thereby extending the service life of the roller. Selecting ceramic anilox rollers made of high-quality materials and processes can ensure the long-term stability of the equipment.

Finally, choosing reliable suppliers and service providers is an important guarantee to ensure the quality and performance of ceramic anilox rollers. Suppliers should be able to provide detailed product information and technical support, and be able to provide customized solutions based on actual needs. In addition, the quality of after-sales service is also a factor to be considered when selecting a supplier so that problems can be solved in a timely manner when they arise.

Karton- und Wellpappendruck